Production management

Are you looking for the perfect production management tool? Instant Team handles this task with ease as well.

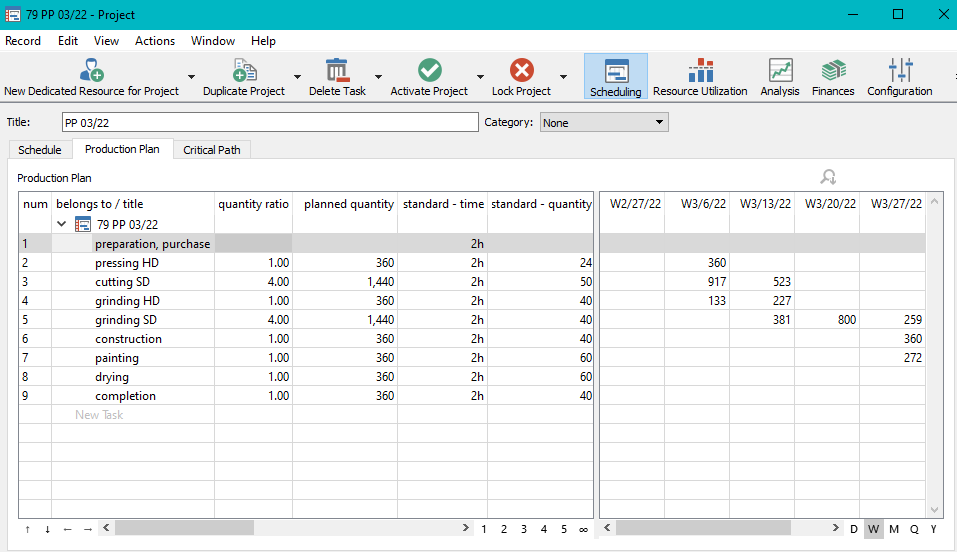

Plan projects according to standards

Set the project type to production and use the standards for the number of pieces or the standards for a given time. This will give you a better overview of labor and standards. You can also use the piece plan of the project and modify the standards continuously, or compare them with the work actually performed.

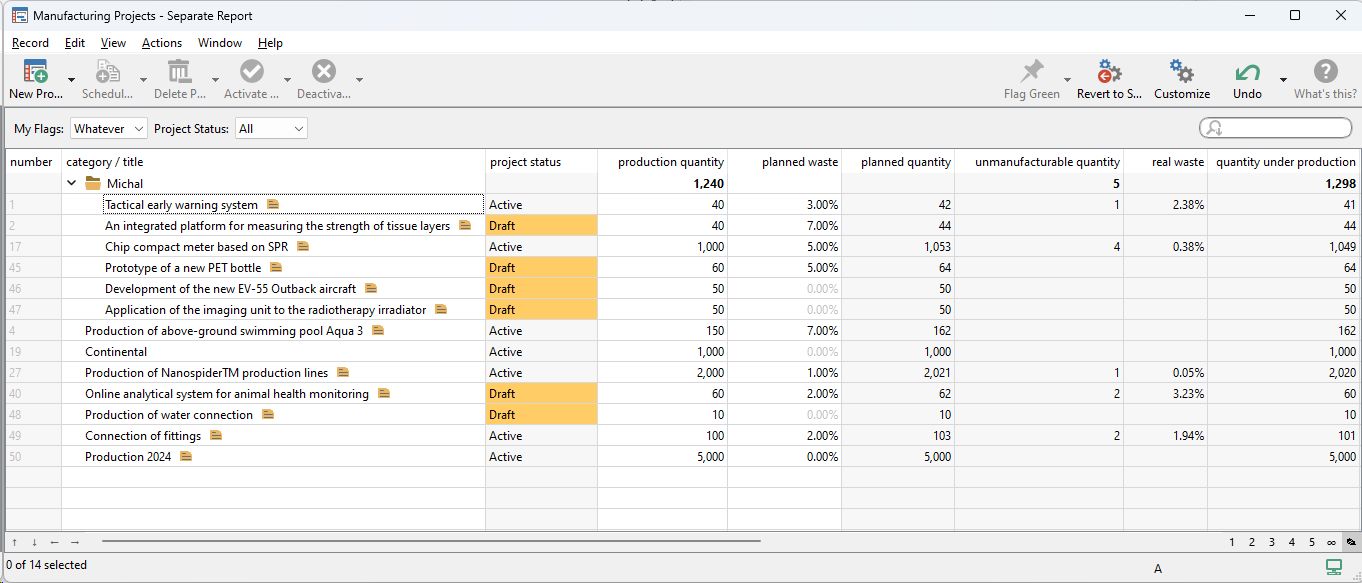

Scrap rate planning and monitoring

Plan to produce more than the required quantity to cover anticipated scrap. Monitor the actual scrap rate and if it exceeds the planned level, be automatically notified and easily enter a production increase.

Easy planning and monitoring of subcontracts

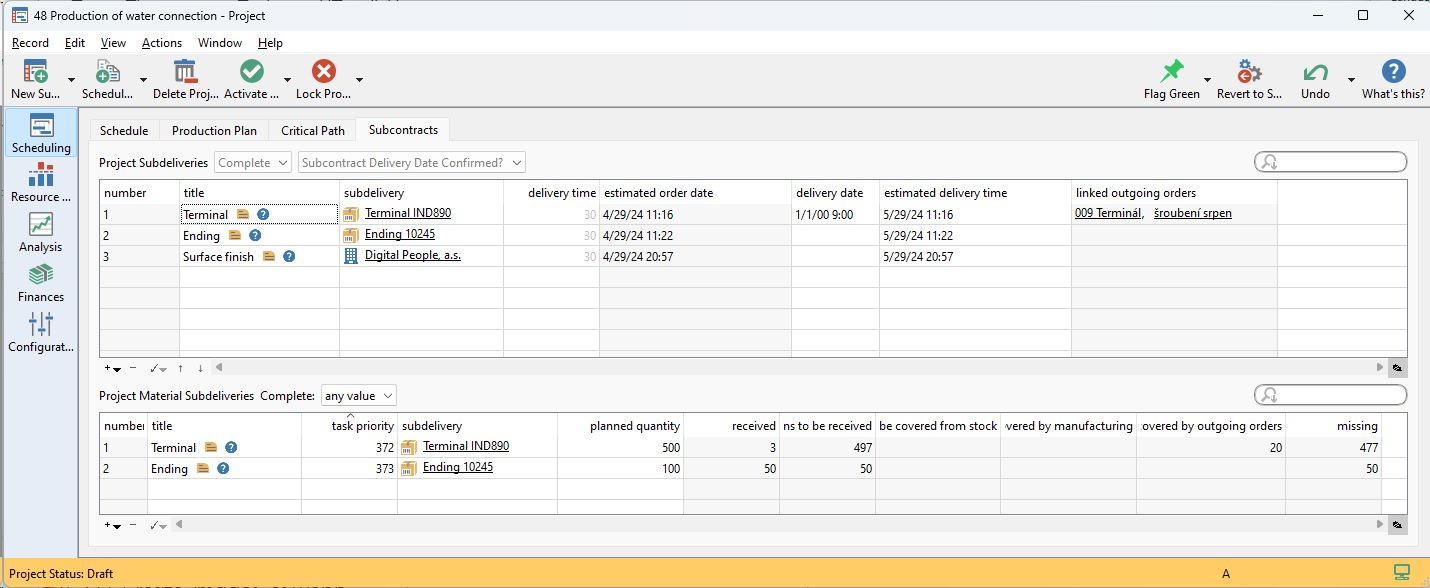

Easily plan subcontracts and collaborations based on supplier lead times and confirmed deadlines. Easily transfer up-to-date information from the purchasing department to projects using the record of issued orders.

Material circulation management

Plan material consumption in projects and unloading deadlines for a project based on quantity in stock, ordered quantity and delivery deadlines, and quantities entered into production, expected production completion dates and required minimum levels. Calculate project material costs based on actual inventory, purchasing, and manufacturing prices.

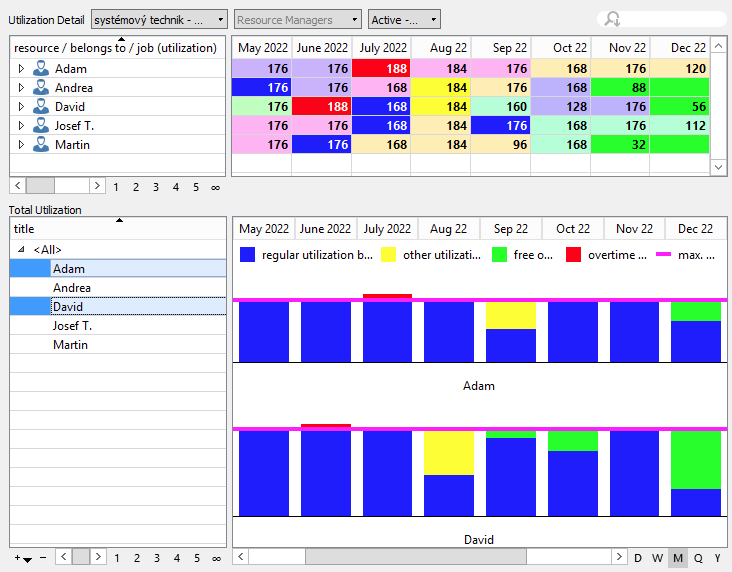

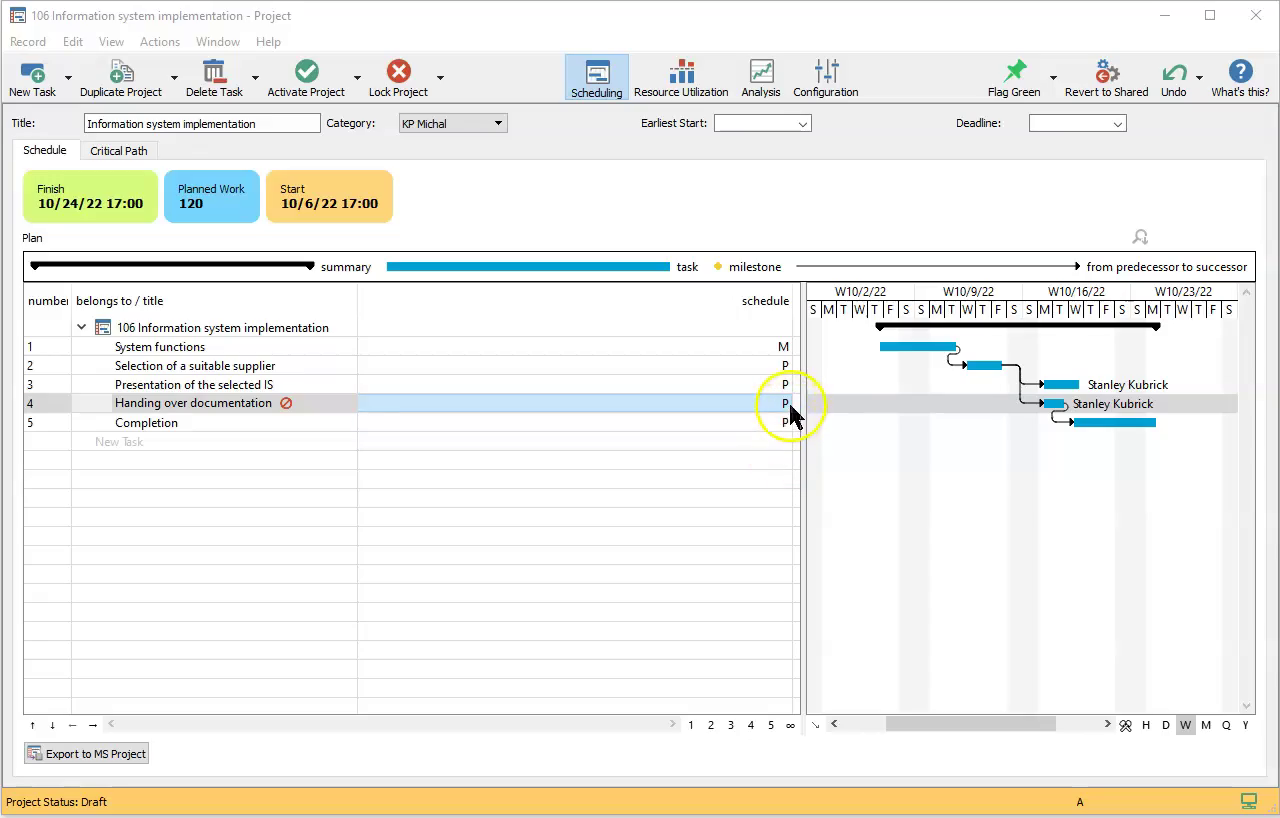

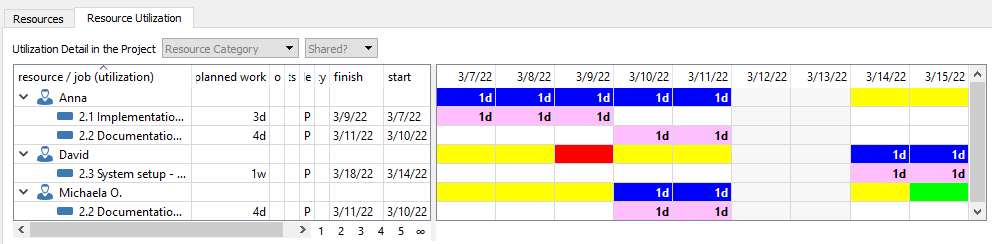

Check work capacity

After assigning tasks to resources, the system will start monitoring their capacity utilization across all projects. You have an immediate overview of whether you have sufficient capacity for the planned projects, or where resources need to be added.

Do not allow resources to be overloaded

You also have the option to schedule deadlines automatically so that resources are not overloaded. The system then automatically finds the nearest available date and schedules the task for it. You can choose from uninterrupted planning to the exact specified capacity (type G and H), planning with the possibility of interruption to the exact specified capacity (type C and E) or flexible planning up to a maximum of the specified capacity (D and F).

Schedule tasks where

multiple resources need to work together

Are there activities in the project where multiple resources have to work together at the same time, for example, does more workers are needed to assemble a large machine, or is a specific machine and its operator needed to complete the task? Assign the task to multiple resources and the system will check if everyone has enough capacity, or schedule it immediately on a date when everyone has time off.

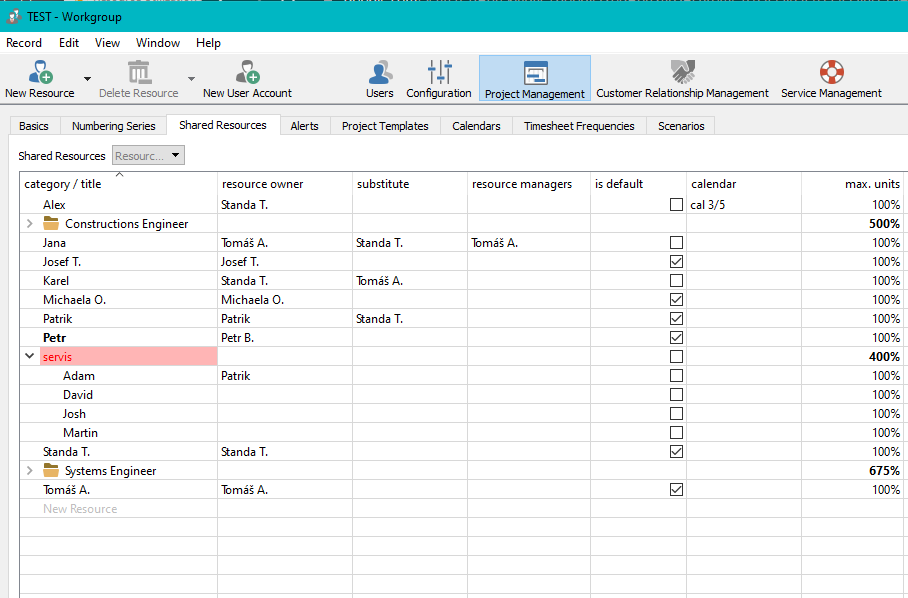

Plan "roughly" on group resources

Resources do not have to represent individual workers or machines, but also, for example, a group of workers with the same qualifications, a company department, a set of identical machines, etc. And you can advantageously combine group resource planning and specific detailed resources.

Tools for production reporting

Print your production waybill note and report produced pieces, rejects, production preparation time, production and idle time easily in a special report. You can easily perform all these operations with the help of pre-prepared QR codes.

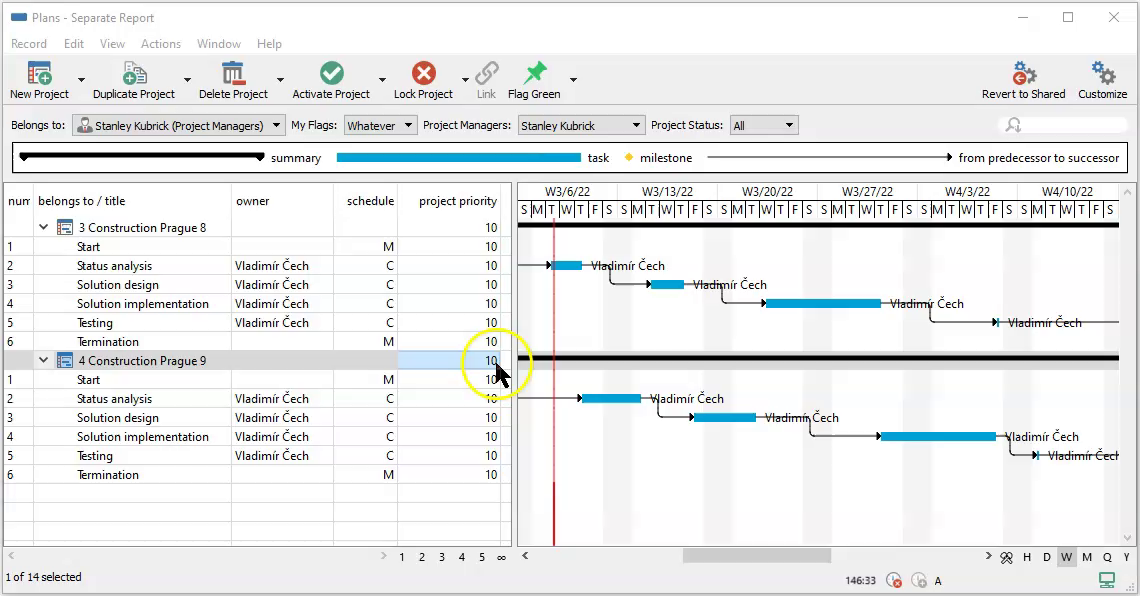

Prioritize capacities between projects and tasks

You determine which tasks will have priority in capacity utilization - use project priorities or the priorities of individual tasks. Does a project need to have a higher priority? No problem. Just change the priority of the project and there will be a rescheduling and you will see what impact this change will have on this project, but also on all other projects.

Analyze production performance

Monitor deviations from planned time standards and from planned scrap by product, operators or templates and thanks to this constantly optimize your production processes.

Analyze the critical path in multi-stage production.

Are you planning multi-stage production where you first produce semi-finished products, then parts from them, followed by various subassemblies and assemblies – all across multiple production batches? Do you need a clear overview of which batch follows which, and which activities are critical to meeting the final deadline? Instant Team now displays implicit links between individual batches and subcontracts, and allows you to analyze the critical path across all batches.

60 days overview of all dates, capacities, inputs and outputs about each project and completely free.

All rights reserved, Created by eBRÁNA Privacy statement